Department: ENGINEERING (CAD & DESIGN)

SPECIALTY METAL & FABRICATION

Market: Industrial

Timeline: 4 Days

Location: York, Pa

CHALLENGE

Prefabricate all piping for an existing 30+-year-old mechanical room then switch it all out over a long weekend.

SOLUTION

Prefabricate all piping for an existing 30+-year-old mechanical room then switch it all out over a long weekend.

Our Walton service team had been working in the building on a few repair projects and was asked to replace all the piping insulation in the building due to continued condensation problems. When they removed the insulation from the mechanical room, they found it was severely deteriorated and needed to be replaced.

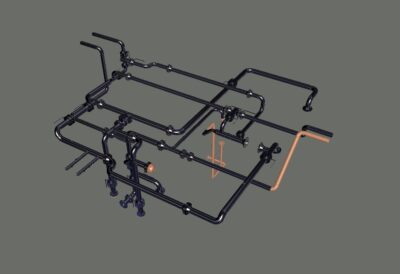

This was a good opportunity to use a laser scanner. Walton’s virtual design department went to work laser scanning the room and creating a 3D model of the existing room. From that model, we were able to draw new piping. We created fabrication drawings for each piece of welded schedule 40 pipe being replaced. The detail of the scan allowed him to recreate all of the branch connections, existing tie-in locations, and all of the taps needed for gauges and instrumentation. Our fab shop then went to work welding up the 26 sections of pipe needed to complete the project. All sections we fully welded out with a flange on either end for quick installation.

Our piping crew then went to work on a Friday morning removing all the deteriorated pipe and loaded into a dumpster to be recycled. Over that weekend they installed all of the new piping, section by section. By Monday morning they only had a few “field connections” to make at the air handler and boilers. Within a few hours, the system was filled and back in operation making heat for the office building.

Overall the job went well and was a great team effort. I’m proud to say the job was completed on schedule and within budget.

[doc id=5506]

Walton & Company

Pennsylvania

1800 Industrial Hwy

York Pa 17402

717.755.9030

3320 Concord Road

York Pa 17402

717.840.2258

Md

150 Lakefront Dr

Cockeysville, Md 21039

410.891.8631

Contact Us Today!

Blog News

Breathing Easier: The Importance of Indoor Air Quality

In today’s world, health and well-being are more important than ever. However, high humidity and poor HVAC and ventilation systems can make breathing difficult and compromise indoor air quality (IAQ). At Walton & Company, we […]