New Equipment & Burner Retrofits

Walton & Company designs, fabricates, and installs new equipment including batch ovens, conveyor ovens, furnaces, thermal and catalytic oxidizers.

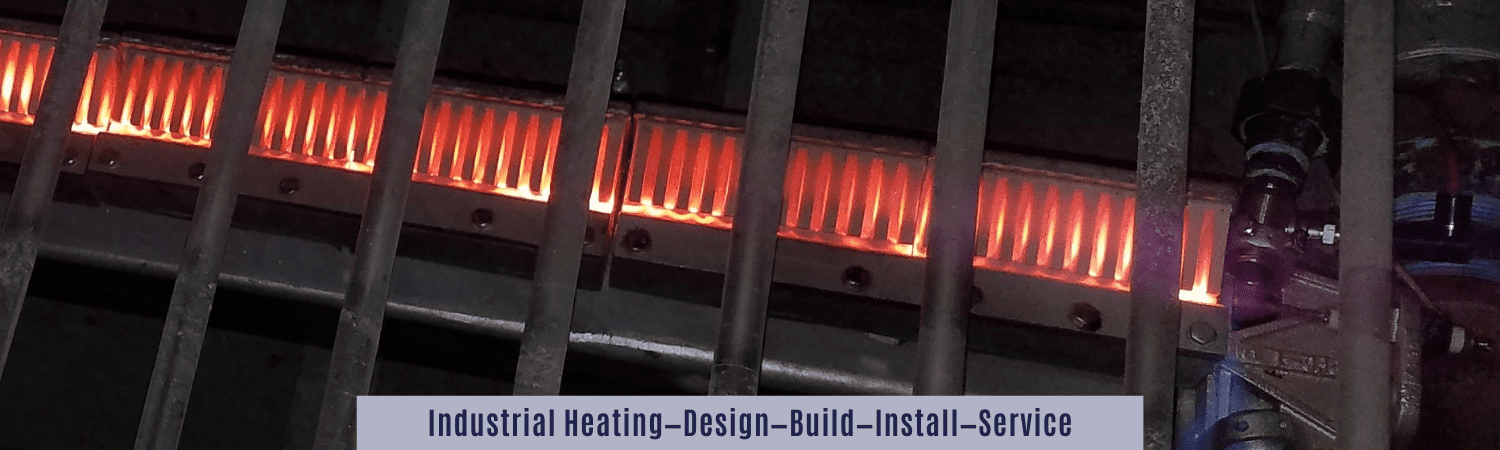

Walton & Company designs, fabricates, and installs new equipment including batch ovens, conveyor ovens, furnaces, thermal and catalytic oxidizers. We provide burner retrofits for existing ovens, furnaces, and oxidizers. Burner types include:

• Air heat burners

• Medium and high-velocity furnace burners

• Self-recuperating burners

• Infrared burners

• Ribbon burners

Walton & Company Industrial Heating

INDUSTRIAL HEATING EQUIPMENT | DESIGN-BUILD | INSTALL

Our team of engineers, designers, experienced fabricators, and trained installers can develop and implement a solution for all types of industrial heating applications for your facility. Whether it's a batch oven, conveyor oven, baking oven, or dryer, Walton & Company's experienced design team will work with you to customize a solution that operates efficiently and safely while meeting your production demands. Walton & Company manufactures industrial heating equipment in our 36,000 sq. ft. fabrication facility. The employees in our fabrication facility are skilled craftsmen who take pride in their workmanship and will work diligently to ensure your system is delivered on time.

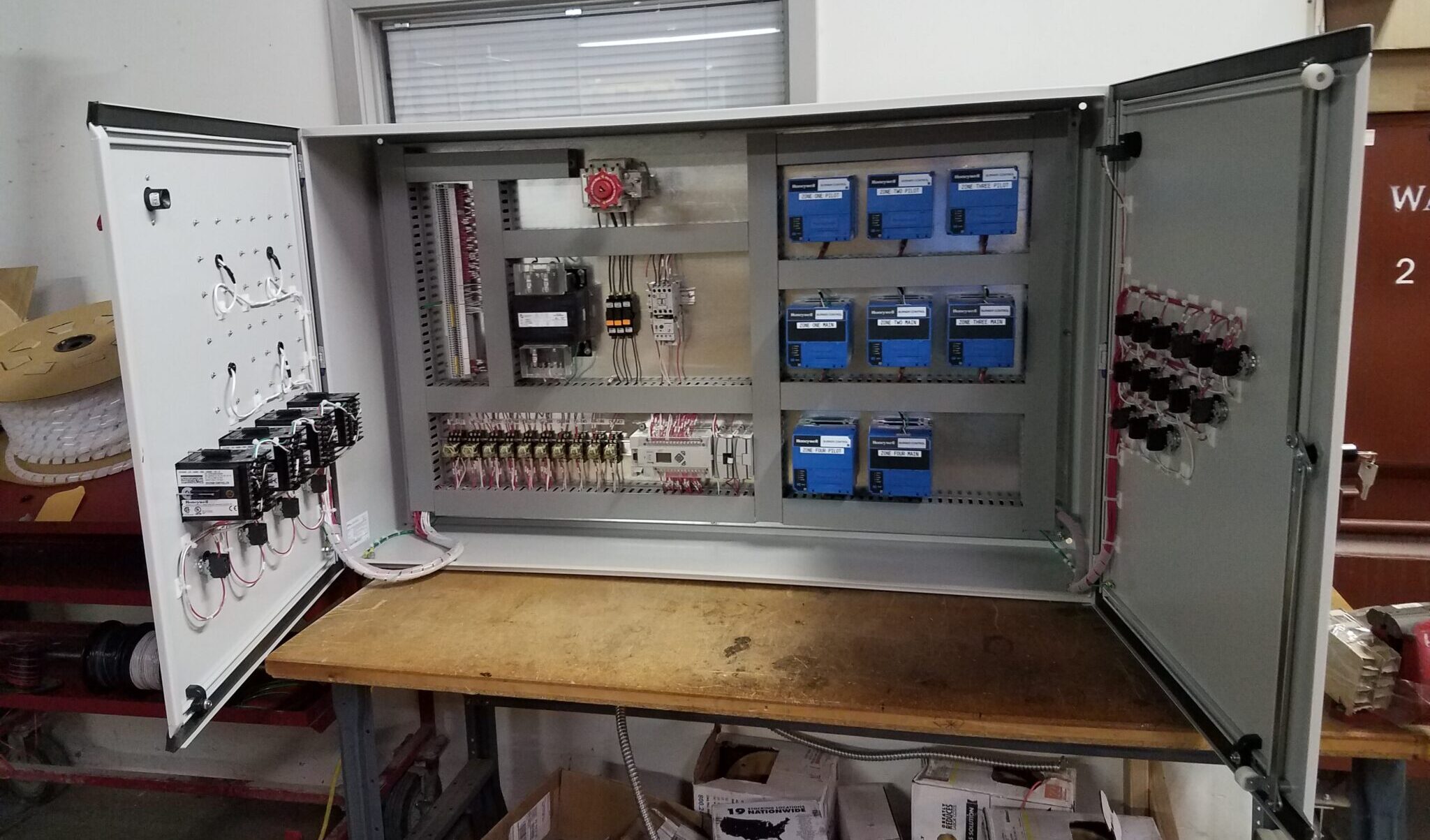

We design our equipment using nationally established suppliers of burners and fuel train equipment. Control panels for burners and combustion systems are designed and fabricated in our facility and can be customized to meet your plant's standards.

BURNER RETROFITS

Walton & Company can provide burner retrofits to increase fuel efficiency or meet more stringent emission standards. We can replace obsolete, unreliable and worn-out fuel equipment and perform safety upgrades to make sure your industrial heating system meets today's safety requirements.

SERVICE / START-UP / INSPECTIONS / TRAINING

Walton & Company has a trained staff of service technicians that provide the following services to ensure your industrial heating equipment performs efficiently and safely.• Start-up, on-call troubleshooting, and preventative maintenance of burner systems and controls

• Combustion system safety audits of your oven, dryer, or furnace to meet NFPA requirements for annual testing

• Training for operators and maintenance personnel to comply with NFPA 86 requirements

• Burner and control loop tuning

• Burner gas train, flame safeguard, and temperature controller upgrades

Whatever the application, Walton can handle all your industrial heating requirements with ease, on time, on spec, and to your satisfaction. Contact us today to discuss your next project!

PA

Walton & Company

1800 Industrial Highway

York, Pennsylvania 17402

United States

Phone: 717-755-9030

Fax: 717-757-5115

Shop

Walton & Company

3320 Concord Road

York, Pennsylvania 17402

United States

Phone: 717-840-2258

Fax: 717-757-5115

MD

Walton & Company

150 Lakefront Dr

Cockeysville, MD 21039

United States

Phone: 410-891-8631 & 410-891-8758

Fax: 410-891-8763